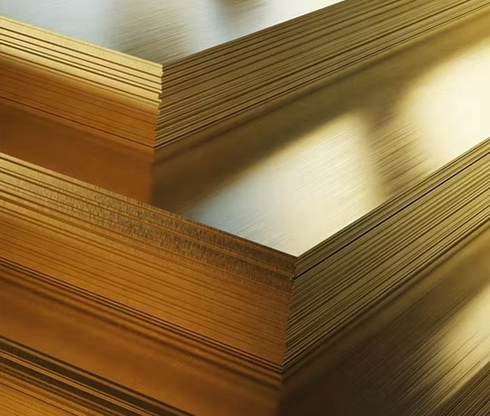

Home Brass Sheet Datasheet

Brass sheets are an alloy of Copper (Cu) and Zinc (Zn), offering a combination of durability, corrosion resistance, and aesthetic appeal. They are widely used in decorative, architectural, electrical, and industrial applications.

Exact composition varies depending on grade – CZ108, C260, C280, etc.

| Element | Percentage (%) |

|---|---|

| Copper (Cu) | 60 – 70 |

| Zinc (Zn) | 30 – 40 |

| Lead (Pb) | ≤ 0.5 (in free-cutting brass) |

| Iron (Fe), Tin (Sn), Others | ≤ 0.1 |

| Property | Value (Approx) |

|---|---|

| Tensile Strength | 250 – 500 MPa |

| Yield Strength | 100 – 350 MPa |

| Elongation | 15 – 45 % |

| Hardness (HV) | 60 – 160 |

| Modulus of Elasticity | ~ 100 – 110 GPa |

| Property | Value |

|---|---|

| Density | 8.4 – 8.7 g/cm³ |

| Melting Point | ~ 900 – 940 °C |

| Thermal Conductivity | ~ 120 W/m·K |

| Electrical Conductivity | 25 – 30 % IACS |

| Coefficient of Thermal Expansion | ~ 19 x 10⁻⁶ /K |